When you’re shipping hazardous materials the term “liquid rated packaging” might come up. So where does the term come from, what does it mean, and why does it matter?

A Quick History

The Department of Transportation (DOT) regulates packages shipped with hazardous materials in the United States. The DOT adopted the “performance oriented packaging” standards from the UN. That’s why you’ll see a UN marking on packaging rated for transporting hazardous material in the United States. Companies that produce these containers or recondition them get the UN marking by testing to ensure that the packaging meets performance standards. You’ll need to match what you plan on shipping to a packaging that meets or exceeds the standards required for your material.

It’s important to learn all of this because the DOT dictates that it’s the onus of the shipper to choose the correct packaging for their materials and not the manufacturer or distributor.

Identifying and Understanding Liquid Rated Packaging

There are two types of performance testing for packaging, solid and liquid testing. Solid rated packaging is for solid and semi-solid material like contaminated soil, asbestos, batteries, detergents and E-waste. Liquid rated packaging is for liquid materials like fuel, oil, antifreeze and cleaning chemicals. Let’s get into more detail about identifying liquid rated packaging.

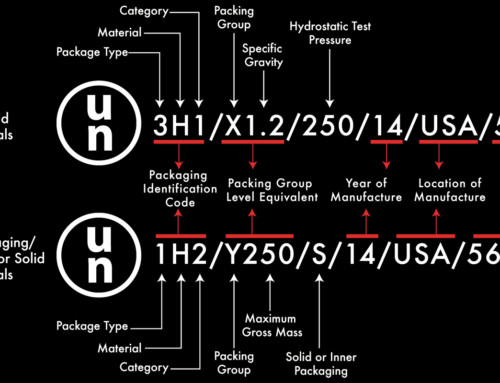

To identify if packaging is rated for liquids you’ll need to first find the UN number. It’ll look something like this UN 1A2/Y1.2/100/16. The first set of numbers is the container type. 1 stands for drum A for steel and 2 open head. This first set of numbers is the same for both liquid and solid rated containers. For more information about what they mean see our article here.

The second set of numbers and letters is where liquid and solid rated packaging differs. Liquid rated containers will have a letter X, Y, or Z followed by a number close to one. The letter represents the packing group (pg) of material the packaging can safely contain. X is for pg 1,2 or 3, Y for pg 2, or 3 and Z for pg 3. X is for the most hazardous of materials and it has the most difficult performance standards for testing. Y is a medium hazard and Z the least hazardous. Packaging must pass more difficult drop and stack testing to receive a higher packing group rating. The number after the packing group letter is the maximum specific gravity of the liquid the container can be used with. Specific gravity is the relative density of a liquid compared to water. Water has a specific gravity of 1.000. You can see examples of this with everyday items found in your home. A liquid with a specific gravity less than one, like olive oil, will float on water and a liquid with a specific gravity more than one, like honey, will sink when added to water. The higher the specific gravity the denser the material so that’s why they sink or float when mixed with water.

The next set of numbers indicates the results of the hydrostatic pressure test. This number is the pressure in kiloPascals (kPa) that the packaging is tested to be capable of withstanding without leaking. The test is conducted by filling the container, usually with water at a particular temperature, and then adding air pressure. If the container doesn’t leak after 5 minutes for steel or 30 minutes for plastic containers, then it passes the test. For packing group one (pg 1 or X rated) containers the test pressure must be at least 250 kPa (36 psig). So why is this important? Imagine a drum filled with a volatile liquid sitting in a trailer on a hot day. By definition a liquid that’s volatile is easily converted to a gas. As the temperature goes up, more and more of the volatile liquid changes to gas. The gas then fills the drum adding pressure as it tries to escape. Without the right container you can expect that the container will burst and leak. That’s why you’ll want to know that the container you’re using for the volatile liquid has been hydrostatic pressure tested and wont leak during transportation.

The last set of numbers in the U/N number is the year of manufacture of the container and country of manufacture. In the example 1A2/Y1.2/100/16. The 16 indicates that the container was manufactured in 2016. For containers manufactured in the United States you’ll also find USA at the end of the U/N number.

If you have any questions or need more information feel free to post them below.